Capstone Project: Transforming Waste into Circular Design

A Case Study on Circularity

This capstone project focuses on circular, material, and chair design. The goal was to test new ways to transform waste into raw material, and then apply it to a design.

Circularity entails that the life cycle of a product follows a circular path and not a linear one. Many of our day-to-day products follow a linear path that begins with the extraction of raw material then the manufacturing of products followed by the disposition leading to harmful waste pollution. Circularly designed products on the other hand can either be repairable, reused for parts, recycled for material, or biodegradable. Meaning the material cycle loops.

Link below for an in-depth look at the project.

Material Samples derived from Rice Hulls

Finding the Right Material

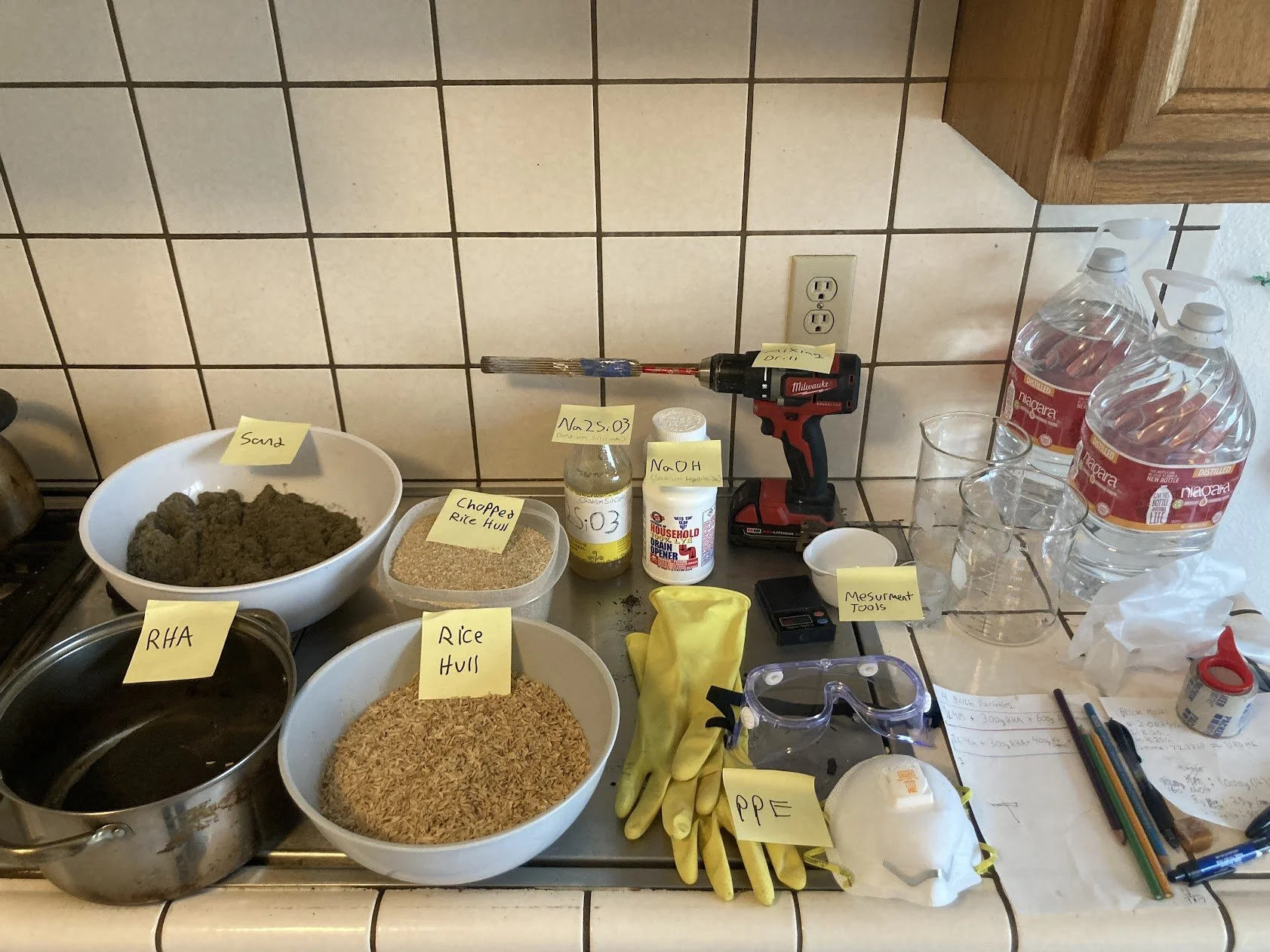

In order to take circular design to the next level, waste can be synthesized to become the raw material. Rice Hulls, a byproduct of rice farming, were this material for the project. Due to their locality (90% of California rice comes from Sacramento county), and their abundance (about 3.9 million kg are produced a year in the US). Frontier AG kindly provided 200ibs of rice hulls for this project.

Rice Hulls

Frontier AG, Davis CA

Rice Farming, Sacramento county

Frontier AG, rice hull packaging site

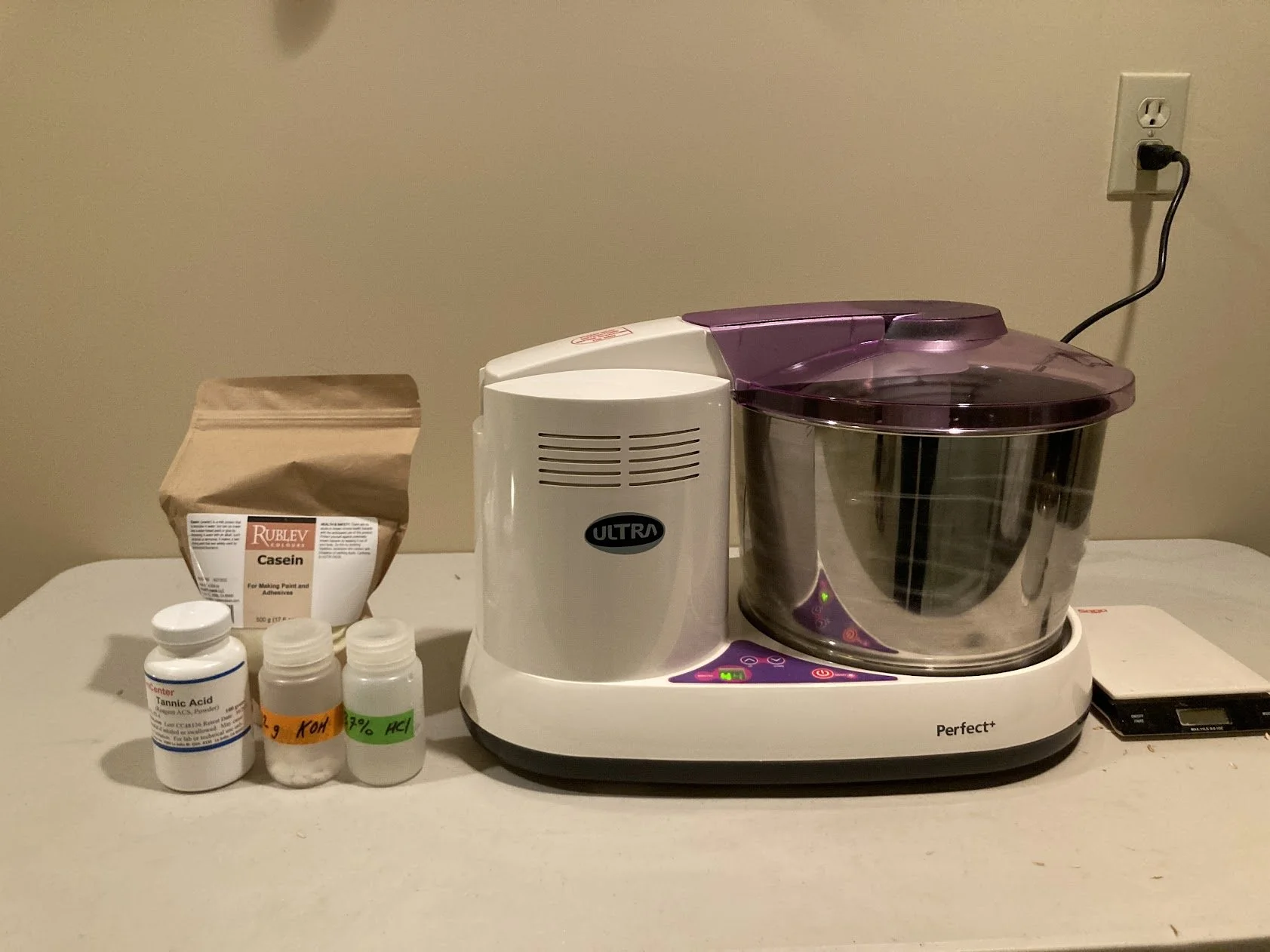

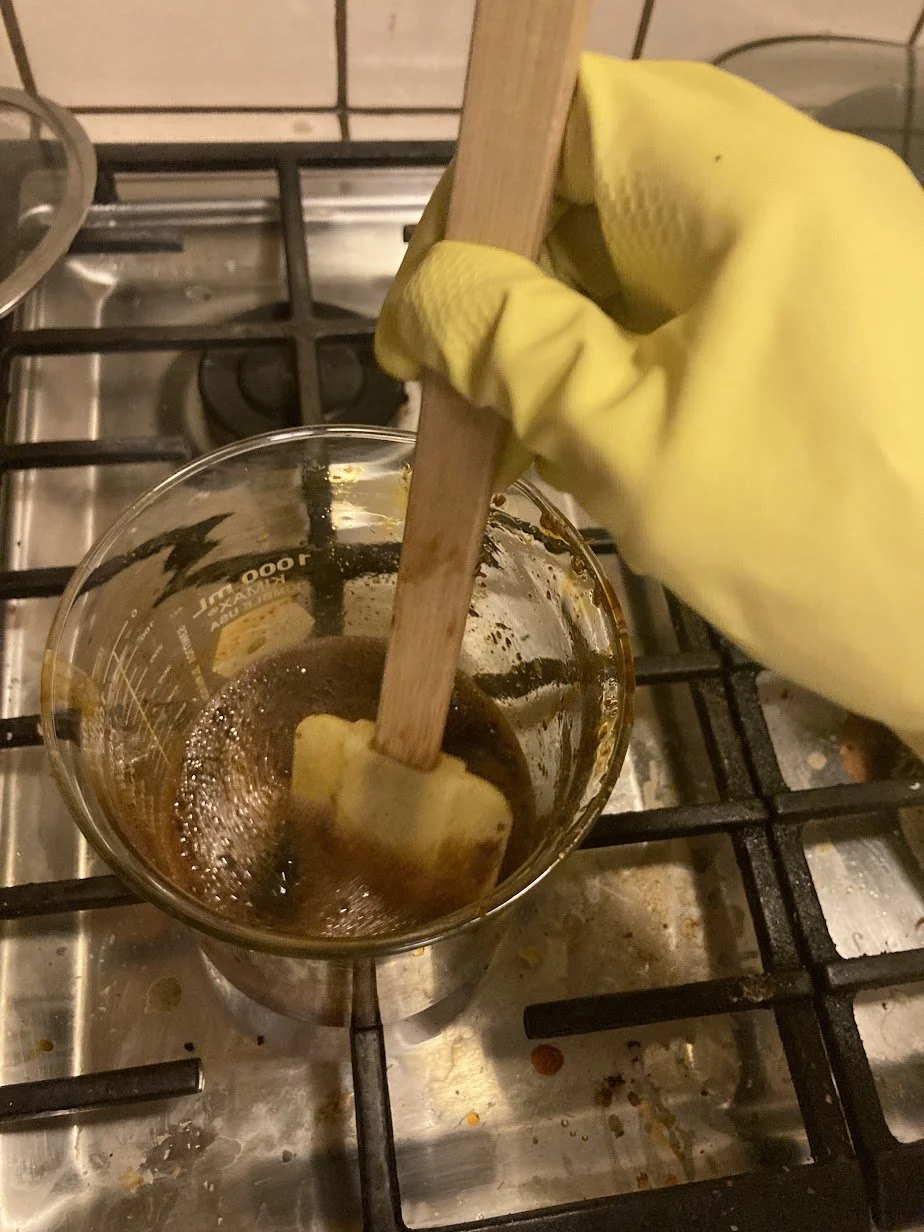

Experimentation

The experimentation phase was the longest of the project which consisted of rouge experimenting, in-depth research, comprehension of chemistry, and a lot of trial and error.

Material Deliverables

The final material deliverables are all made from a majority of rice hulls and were synthesized utilizing a variety of tactics and biopolymers. Furthermore, these rice hull materials can be used within circular designs as they are non-toxic, and are recyclable, and biodegradable. Furthermore, they act as substitutes for lumber, cement, and plastic, all of which are raw materials that have a massive negative toll on our environment.

rice hull plastic

rice hull concrete samples

rice hull composite board (1)

rice hull composite board (2)

Design Process

Applying Rice Hull Materials to Chair Design

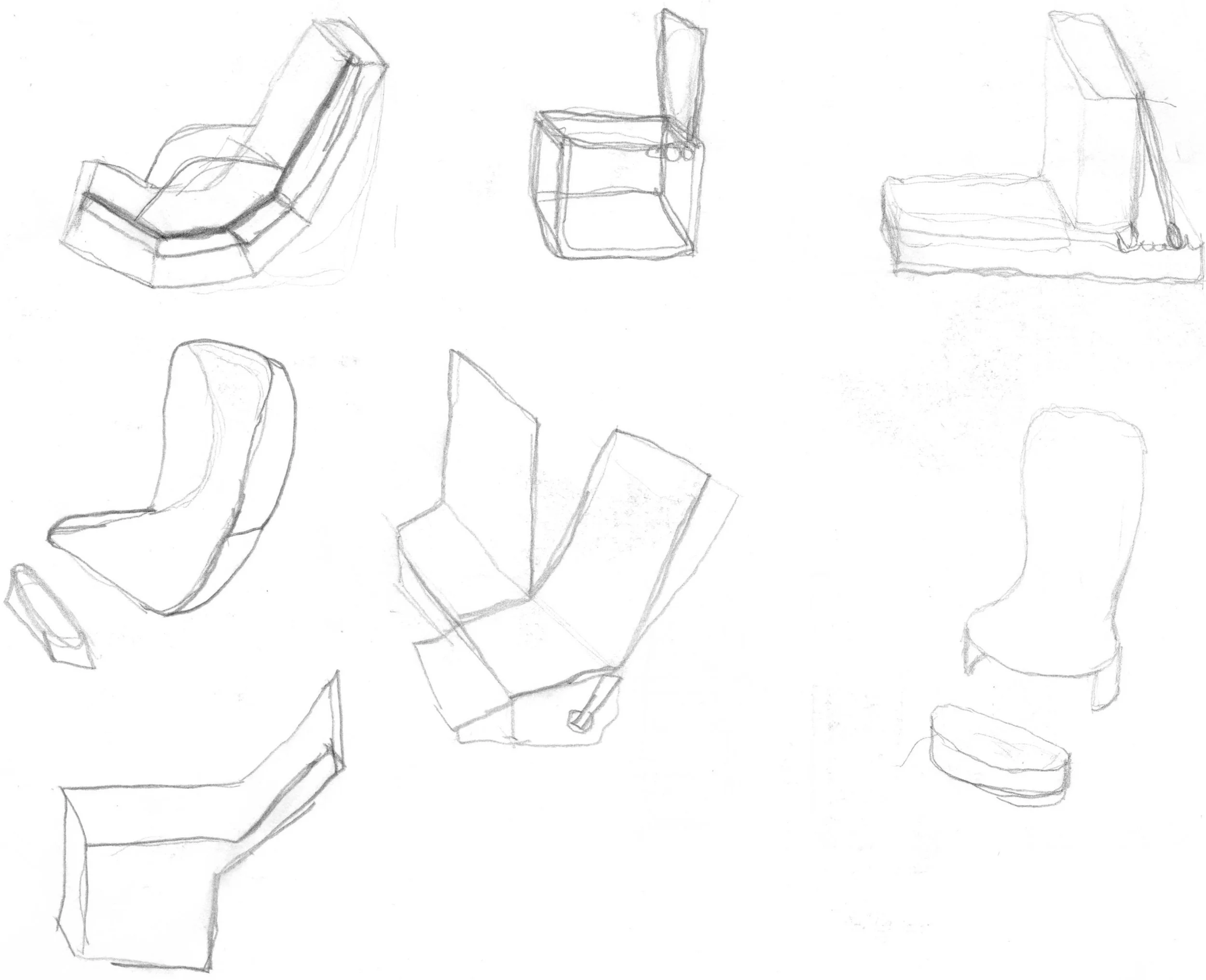

After the synthesis of the materials, it was time to apply them to a chair design to showcase the chair’s complete circularity.

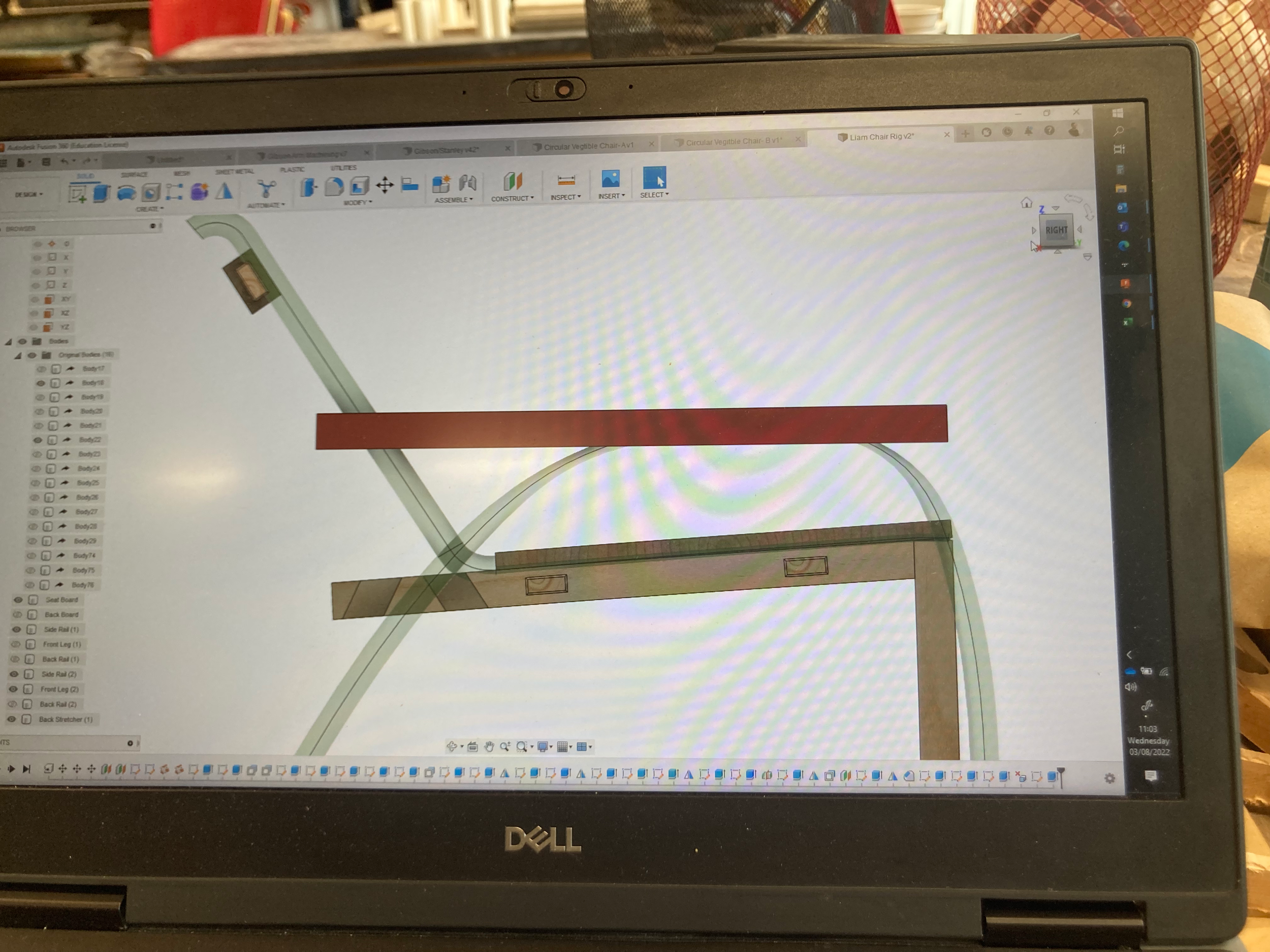

The chair design process was pretty straightforward. The only constraint (other than material choice) was it had to be manufactured without glue, or nails, and with a minimal amount of components which promotes fixability and circular design as a whole. The process began with an abundance of sketches, and 3D modeling, followed by building a rig, and lastly prototyping maquettes.

Final Maquette

side siew: panels made from rice hull concrete

front view

Cushion made from bio plastic and rice hulls.

seat & back made from rice hull lumber.

back view

Although it’s been said time and time again, our societies and ecosystems are on a brink of chaos due to global warming and overconsumption. Leading to toxic and dangerous living conditions for all species on Earth. On an individualistic level, we need to be better. On a product designer and manufacturer level, we need to be the best. Starting with implementing a cultural norm for designers, manufacturers, and retail companies in which we adopt circular design methods and consider using waste to raw material to build our products.

Throughout this project, I learned the true meaning of what it means to be a designer. It means looking past what you already know, leaving the design realm to enter new realms of industries and communities. During this project, I entered the realms of chemistry and farming. Learning a great deal about certain chemicals, theories, and practices, involving both the chemistry field and rice fields. As well as giving me an introduction to being a material scientist.

Conclusion

In Depth Look

Due to the nature of this project spaning over a four-month period, I plan to take it further by calling the rice hull materials up and building both a full-scale chair as well as other products in which it could make sense to use these materials such as rice packaging.